Our Projects

PhotoOlive

PhotoOlive offers the development of combined technologies and integrated systems for the instant ‘on-line’ and ‘on-site’ quality check of olive oil during production and storage.

The key measurable factors of olive oil quality, that are essential for the categorization and pricing of olive oil and olive oil related products are the acidity levels and k values. Up to now, typical state-of-the-art (SOA) methods for determining these parameters rely on manual chemical titrations and/or near-infrared (NIR) spectroscopy. This renders a necessity the specimen transfer to specialized analytical chemistry laboratories, often located away from the production lines and storage departments. Such process is time consuming and costly, while being environmental unfriendly due to production of significant solvent waste.

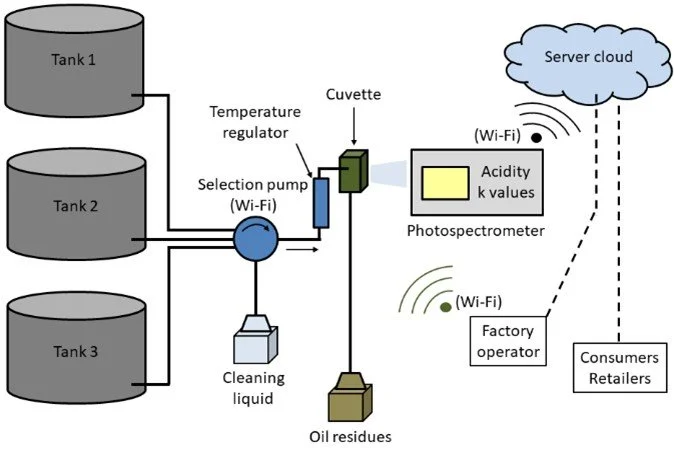

PhotoOlive resolves these challenges upon introducing IoT and innovative technologies for the integration of analytical devices in olive oil production lines and storage compartments of factories. Namely, for the during production quality check the system consists of microcavities for the on-site sampling of the as-produced olive oil, whereas for the post-production storage quality monitoring the PhotoOlive platform utilizes micropipes and custom-made pumps for automatically transferring the sample to the analyser.

Figure 1: Schematic representation of the ‘on-line’ and ‘on-site’ PhotoOlive quality monitoring integrated technology during olive oil production and post-production storage.

Overall, the developed PhotoOlive integrated technology exceeds the current SOA in the following aspects:

i. It renders the quality control of olive oil instant while minimizing the cost.

ii. It offers regular check without the need of additional mankind effort and personnel costs.

iii. It allows the direct dissemination of olive oil parameters to producers, factory operators, and customers.

iv. It assists the factory operator to select optimum milling conditions towards achieving optimum product quality.

v. It allows the instant selection of suitable storage tank immediately after production.

For more information on custom made solutions and the PhotoOlive technology please contact the company’s CSO Dr. I. Konidakis (i.konidakis@k2mscientific.gr)